The first site in France to use a green hydrogen-powered vehicle is currently underway at Saint-Cyr-l'École. A decarbonized Haulotte aerial work platform is being used to carry out the external insulation of a social housing building.

A real-life test

Strategic feedback to accelerate the energy transition

*The scissor lift dowes its name to the way it elevates. As it rises, the arms contract and take the shape of scissors, allowing for vertical elevation only. They are divided into two categories: For slab floors: Electric scissor lifts can be used on all types of stabilized surfaces. They are highly flexible, offering more compact dimensions than diesel versions, and can be used indoors or outdoors, even at full height and without load restrictions. For rough terrain: With their large platform, scissor lifts have a higher load capacity than other platform types. They can lift up to 4 people for demanding tasks. Platform extensions offer additional reach and workspace. Their straight elevation makes them very easy to handle. Thanks to their high clearance and slope capability, rough terrain scissor lifts operate on the roughest terrains. Outriggers provide maximum stability. Some scissor lift offers an electric alternative to diesel for rough terrain worksite, allowing for indoor work with zero emissions and silence.

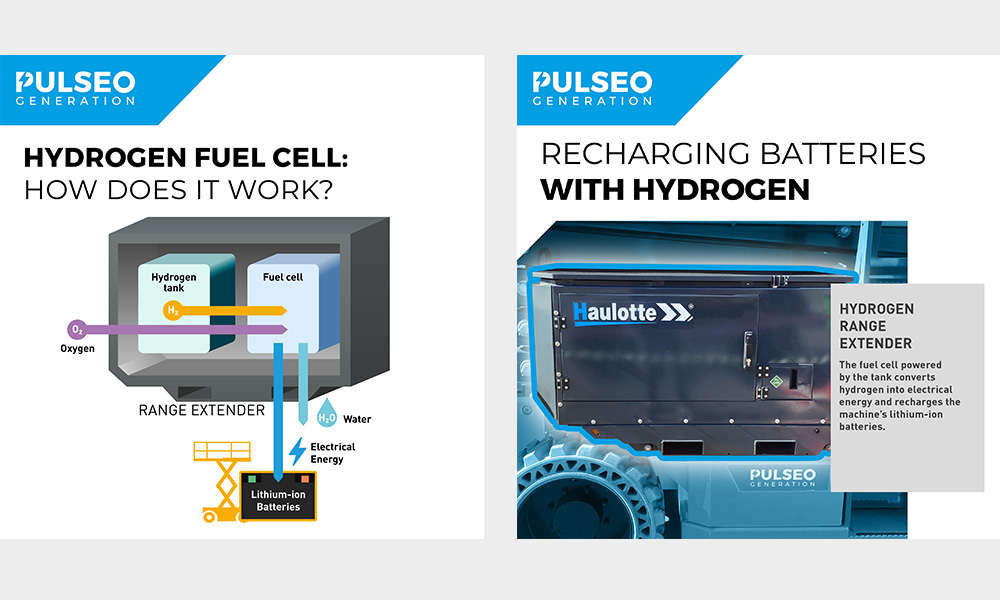

**A Range Extender: lPULSEO scissor lifts can accommodate a removable and interchangeable Range Extender between other models of the PULSEO Range. The Range Extender allows independence from the electrical grid by recharging the batteries on-site. The operator maintains full machine capabilities during this ultra-fast charge, or can be done during a break.

PRESS CONTACT:

Laure de Longevialle (Equans France) : +33 (0)6 62 34 71 77 - laure.de-longevialle@external.equans.com

Carine Ploton (Haulotte) : cploton@haulotte.com

About Equans France Group

About H2SYS

About Roth H2